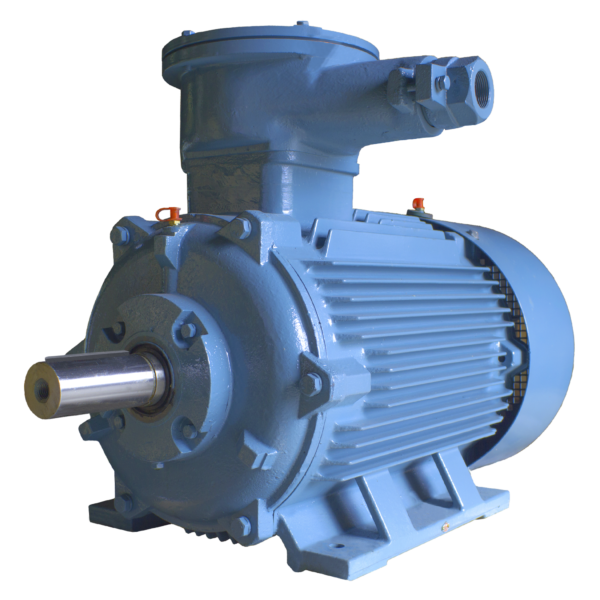

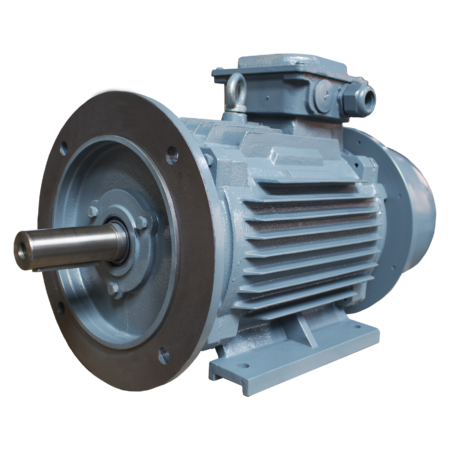

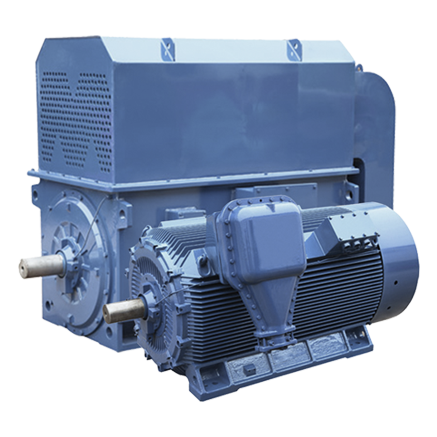

EP series three phase explosion proof motors are uniquely designed and built to contain the sparks within the motor to prevent ignition of external combustible vapours contained in the surrounding atmosphere. The explosion proof characteristic enables the motor to be safely used in hazardous environments.

Certifications:

ATEX EExd IIB T4 or EExd I

ATEX EExd IIC T4