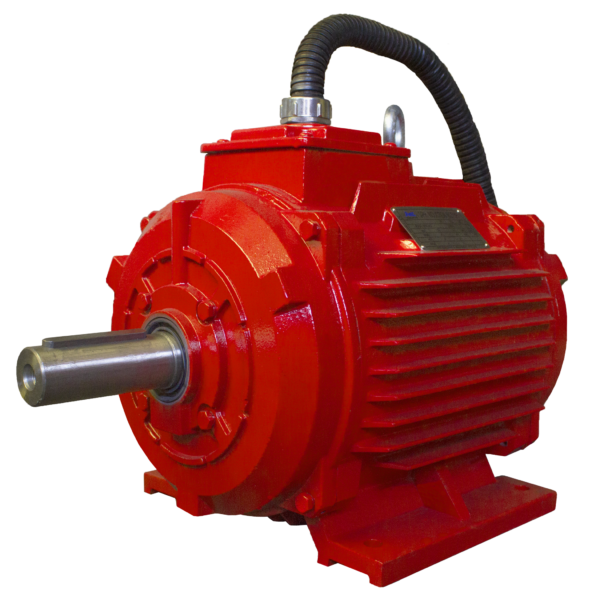

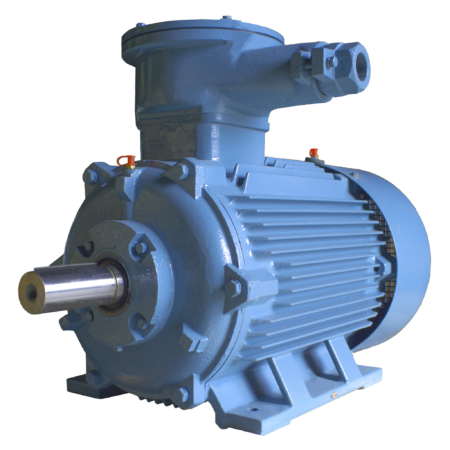

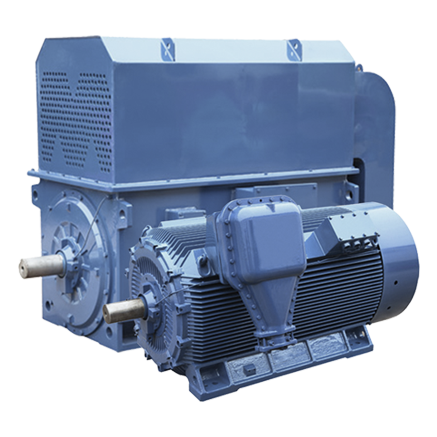

ATT Smoke Extraction Motors are specifically designed to meet demanding and critical industrial applications such as fire emergencies and more. Smoke extraction systems are employed in a wide range of environments including large buildings, shopping malls, factories, warehouses, enclosed parking lots, tunnels, among others.

This motor is made to provide a life-saving role through fastest possible extraction and clearance of toxic fumes and smoke at high temperature during emergencies. Incorporating these smoke extraction motors into your rescue or emergency systems may mitigate damage to property and financial loss by preventing the accumulation of smoke, reducing environment temperatures and the delay in rate of fire spreading.

ATT Smoke Extraction Motors are compliant to EN 12101-3 which determines the standard for “Smoke and Heat Control Systems”. All ATT Smoke Extraction Motors are tested and certified to operate for two hours at a temperature of 250°C, 300°C and 400°C.

| Class | Temperature (ºC) | Duration |

| F250-120 | 250 ºC | 2 hours |

| F300-120 | 300 ºC | 2 hours |

| F400-120 | 400 ºC | 2 hours |